Recently, Zowell Intelligent Forklifts RRE115 model electric double deep reach trucks were shipped to overseas in batch. According to the customized needs of customers, these trucks were made waterproof, freeze-proof and rust-proof.

Project Background

The client of this article is a cold chain logistics enterprise, which is committed to building a green and intelligent cold chain logistics system, and has formed an industrial chain of frozen product warehousing, platform trading, bulk purchasing, cold chain logistics and distribution.

However, the larger the cold storage area is, the higher the operation cost of the enterprise is. The customer wants to obtain stable growth of logistics benefits, and under the recommendation of the partners, they put their eyes on Zowell intelligent forklift trucks focusing on intensive storage in narrow aisles in the hope of helping the enterprise to reduce costs and increase efficiency through the professional and matured intensive cold chain storage solutions.

Underutilization of warehousing

The larger the cold storage area, the higher the daily operating cost of the refrigeration system, and increasing the storage utilization rate becomes the primary choice to control operating costs;

The loading and unloading transportation process is time-consuming, the loss of goods is large, and the operational efficiency needs to be improved;

The temperature of the customer's cold storage is between -18℃ and -25℃, and the forklift trucks need to keep rotating in the high and low temperature environment in their daily work. Therefore, when purchasing the forklift trucks, they have strict requirements for the endurance of the products, the stability of the equipment, and the durability of the low temperature, etc. The forklift trucks can be used in the cold storage of the customer's cold storage.

01

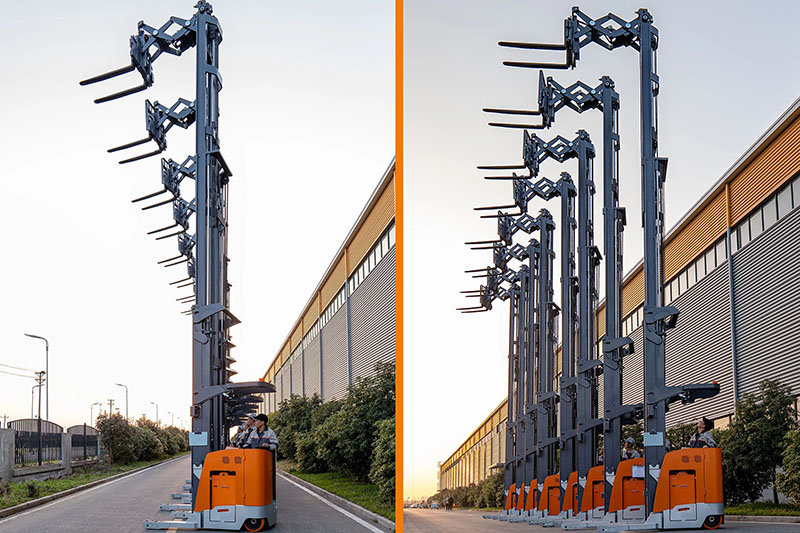

This batch of cold storage special type double deep reach truck, the maximum lifting height of 11.225m, shear fork forward distance of 1030mm, a single aisle can manipulate four rows of shelves;

After being put into use, the horizontal and vertical available storage space in the cold storage is completely released, which will increase the storage capacity by nearly 90% for the enterprise and enhance the storage ping efficiency, thus reducing the proportion of expensive cold storage operation expenditure.

02

The double deep truck is easy to operate and precise in control, with a maximum load of 1.5T and a maximum speed of 10km/h, which is much better than the traditional forklift trucks previously used in terms of maneuvering simplicity and entry/exit efficiency. After the cold chain products are unloaded and transferred to the platform, the forklift driver can quickly transfer the palletized goods to the cold storage to keep the goods in the best condition.

03

The forklift trucks for cold storage, which have been fully rebuilt by Zowell, can operate normally in the lowest -25℃ environment. The body and door frame have been treated with anti-rust treatment, the hydraulic oil, gear oil, solenoid valve and other hydraulic systems have been treated with professional level anti-freezing treatment, and the service life of the electrical parts after waterproofing and low-temperature resistance treatment will be longer, and together with the professional drive wheels, the forklift trucks can easily cope with the operation of the low-temperature cold storage which is prone to skidding even though it is easy to do so.