01 Customer background

The customer is a head enterprise in the auto parts industry, which is favored by domestic famous car companies for its high-quality and diversified auto parts. At a time of fierce competition in the industry, the customer wants to build intelligent unmanned warehousing to enhance the competitiveness of the enterprise with a more efficient and smarter logistics model.

02 Project Difficulties

A wide range of products, accompanied by a large number of orders placed, production, storage storage space is difficult to meet the subsequent demand.

Expansion of production capacity, loading and unloading, transportation, storage of labor demand increases, high labor cost expenditure;

Manual inventory is inefficient with errors and has a low degree of intelligence, which is inconsistent with the company's current development orientation;

Employees are limited by their skill level and physical ability, making it difficult for them to always be in top condition to perform logistics tasks, and occasional crashes occur when they are tired, jeopardizing the safety of property and personnel;

03 Zowell Intelligent Logistics Solutions

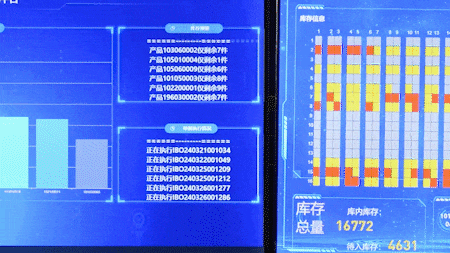

After carefully investigating the customer's site and evaluating the warehouse conditions, Zowell Intelligent Forklift gives WMS warehouse management system, intelligent three-way AGV forklift, automatic conveyor line detection and connection, and three-dimensional shelves as a whole intelligent logistics solutions to help the customer transform from traditional logistics to advanced digital logistics.

ZOWELL

Adopting Zowell intelligent three-way stacking AGV forklift, with a load capacity of 1.6 tons and a maximum lifting height of 9 m. Effectively improving the customer's warehouse capacity rate, the width of the rack stacking aisle is only 1.75 m, and the number of storage spaces is nearly doubled compared with that of the original warehouse.

ZOWELL

Zowell intelligent three-way AGV forklift adopts the hybrid navigation and positioning scheme of laser SLAM+magnetic stripe, which makes the positioning more accurate. The automatic conveyor line detects and connects (automatic volume measurement+automatic weighing+automatic code scanning), and the access to the warehouse is more safe and reliable.

According to the task instructions can completely replace manual equipment docking, material transfer, goods stacking or empty pallet recovery and other highly repetitive work, for enterprises to reduce the demand for labor in the logistics line.

ZOWELL

ZOWELL

The whole vehicle is equipped with multiple safety sensors, which can monitor the intrusion of people and obstacle interference in real time to ensure the safety of operation.

Even in the complex environment of human-machine and vehicle-road collaboration, the vehicle can monitor the surrounding environment in real time when handling and turning, actively avoiding obstacles and eliminating potential safety hazards.

ZOWELL

Zowell AGVs are equipped with automatic charging function without manual intervention, and will return to the charging station to replenish the power when the power is low, which ensures that the AGVs can continuously and efficiently carry out the logistics tasks, and improves the stability of the production logistics.