In recent years, with the leapfrog development of e-commerce platforms, logistics business is expanding rapidly, and warehouse logistics, as an important part of the e-commerce supply chain, also needs to achieve the needs of the client with faster response speed.

The client of this article is a domestic e-commerce enterprise. The client's original model of manual picking, shipping, operating machines for cargo transfer and stacking cannot meet the business development needs, which hinders the enterprise's pace of striving for the first place. The company hopes to take this opportunity to introduce digital technology and open up a new, modern and flexible intelligent storage model through automated logistics solutions.

Helping e-commerce storage intelligence:

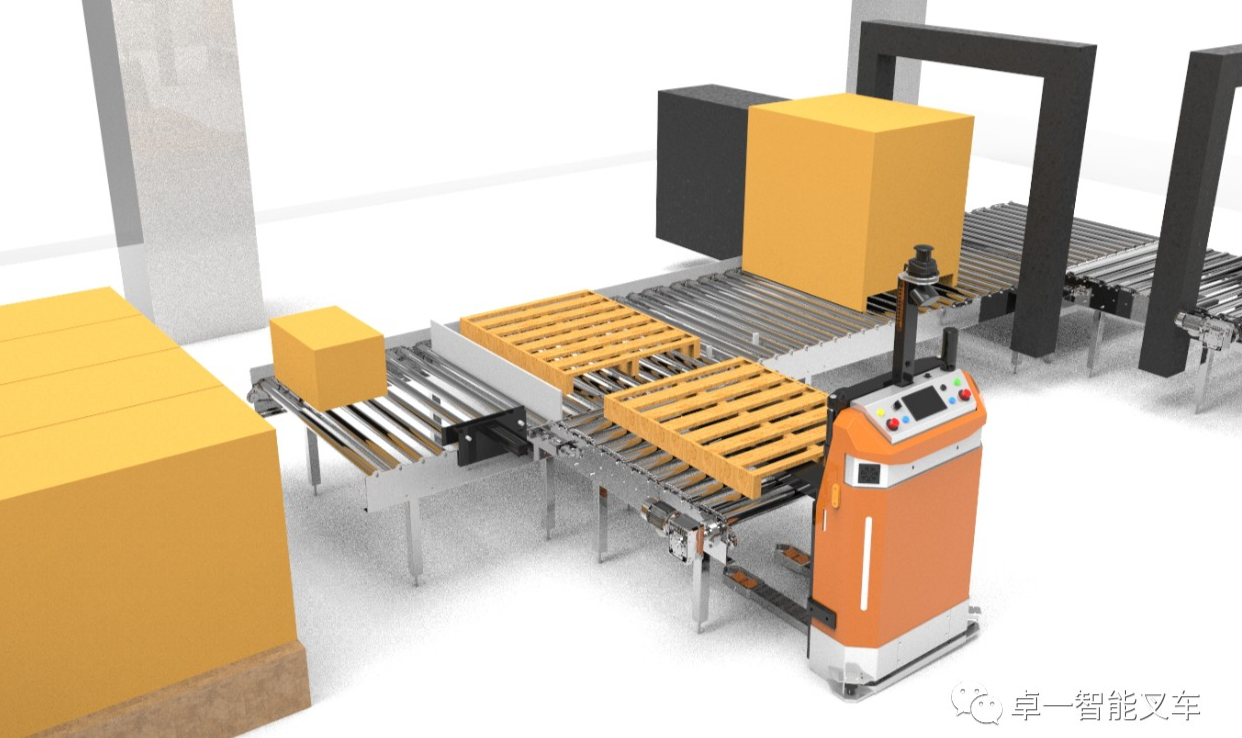

Recently, many MiNi-AGV mini stackers of Zhuoyi intelligent forklifts have been shipped to the enterprise. The addition of key intelligent logistics equipment will help the enterprise speed up order response, reduce order processing difficulties and promote the efficient and large-scale operation process of the enterprise.

The MiNi-AGV mini stacker truck sent to the customer's enterprise has a rated load of 1500kg, a lifting height of 1800mm and a minimum channel width of only 2114mm.

The whole vehicle is compact and flexible, which can meet the application scenarios of different industries. The vehicle is equipped with a mature integrated pump control system, which can realize the smooth lift of forks with pump-controlled rise/proportional fall.

Warehouse planning in the e-commerce industry is different from the traditional industry, with a wide variety and a large volume of goods. Warehouse men drive forklifts all over the warehouse after picking up goods and stacking them haphazardly, which increases the cost of storing goods and demands more and more storage area, and enterprises will be overwhelmed when facing the situation of surge in orders. Therefore, the planning of access routes is one of the important factors to improve logistics efficiency.

After planning the established route for the AGVs to enter and exit the warehouse, we cooperate with the AGV dispatching system to monitor the location information of the pickup and discharge points and the trajectory of the AGVs to ensure that the goods can be delivered intact and accurately.

At a time when labor costs are rising, the application of Zowell intelligent storage equipment, the enterprise's manual from the high-frequency, repetitive handling process to free up. In reducing labor costs at the same time, greatly enhance the efficiency of warehouse operations, to help the enterprise logistics wisdom transformation, to bring better development opportunities for enterprises.

According to the actual needs of this customer's site, we have selected and installed broken pallet detection and obstacle detection modules to ensure the safety of load stacking and handling operations. The vehicle is equipped with LED turn signal lights, and obstacle avoidance radar is installed at the front and rear of the vehicle to prevent collision during the man-machine collaboration.

After years of development, Zowell has opened up its own exclusive technical and market advantages in the field of logistics equipment, and continuously increased its scientific research strength, based on its own electric forklift body, integrated the company's resources to develop automatic guided forklifts and strengthened the technical strength of intelligent AGVs, which has occupied a place in intelligent logistics equipment.

Zowell has devoted itself to researching technology and products, and deeply studied the nature of customers' industries to meet project-oriented customization needs.

By providing unmanned forklifts and new intelligent logistics system solutions, Zowell has helped many enterprises to improve the efficiency and accuracy of warehouse operations, optimize logistics processes and realize the digital transformation and upgrade of logistics links.

Client Case show: